I didn’t get much done on the studio yesterday because, if I’m really honest, I’m so tired of this summer. Yesterday, after Matt and I had finished lunch and I was getting ready to head into the studio to work, Matt checked the weather. It was 106 degrees with a “feels like” temperature of 112. I thought I could push through, but a lot of what I needed to do was outside work. And when I opened the back door and felt that wall of heat hit me in the face, I lost all motivation.

I managed to get my miter saw set up, and cut three pieces of lumber, and I was done. I just couldn’t push myself to do more. I’m so over this summer and this weather, and I’m ready for some cooler fall temperatures to get here. So far this month, we’ve had only one day below 100 degrees. That day, we had a cool 97-degree day.

Anyway, most days I can push through. Yesterday, I just couldn’t make myself do it.

But I did manage to do one thing that I wanted to get done, and that was to fix the toekick on the mural wall of cabinets in the studio. If you’ll remember, I had originally not planned to do a toekick on those cabinets. I had planned to trim out the bottom like I would a bookcase, sans toekick, because I didn’t think I’d actually be using that countertop much.

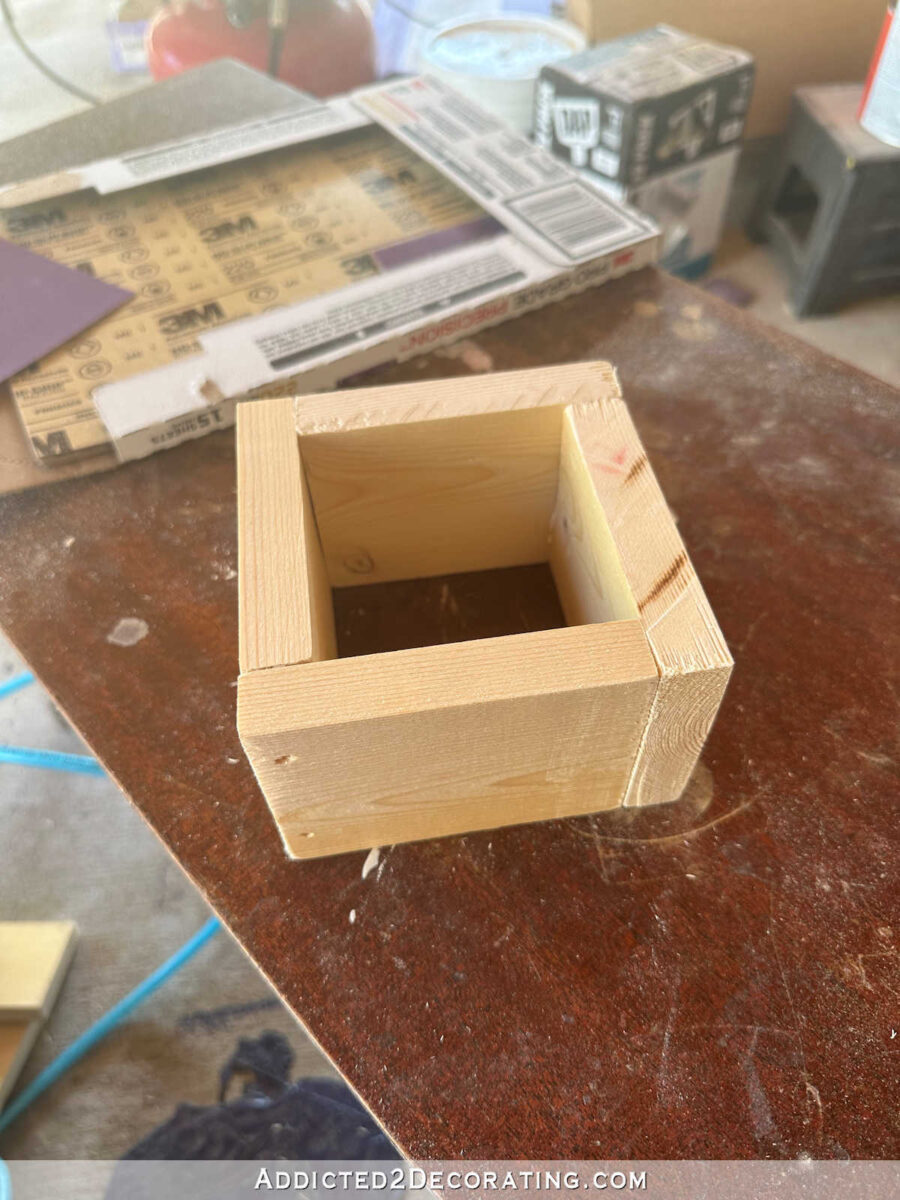

Since the IKEA legs for the Sektion cabinets didn’t fit my need (I needed mine to be shorter than their legs), I ended up making these utilitarian feet…

And then I attached them using my hot glue gun.

Because I wasn’t planning a toekick, I attached those front feet at the very front of the cabinets so that the trim pieces could be nailed directly to those feet and the front of the trim would be flush with the front of the doors and drawer fronts.

So when I got to this point, and realized that I’m actually going to be using this countertop quite a bit, and I needed a toekick after all, I had to find a way to make that happen.

In all of my years of DIYing, I’ve learned that there’s always a solution to problems. I’m generally pretty good at solving those problems, and I’m the type of person who won’t rest until I find a solution so that I can have things exactly like I want them.

Fortunately, this didn’t require a whole lot of thought. Since I only attached them with hot glue, and didn’t use any nails or screws to secure them, this was actually pretty easy.

I simply took my hammer, gave each foot a couple of good, strong whacks on the ends (not in the middle where such force could have broken the front piece of wood), and knocked each foot free from the cabinet.

I know that will bring up the question, “Does that mean that hot glue doesn’t hold well?” Hot glue holds just fine, but of course, it’s not appropriate for every single project where you need to attach one surface to another. It’s fine for some projects, but not appropriate for others.

In this particular case, it was fine, and would have held up perfectly had I not whacked them with a hammer. 😀 After all, these cabinets are all screwed to each other very securely, and then the whole row of cabinets is screwed to a horizontal board which is screwed into studs. The entire row of cabinets is very secure, and these feet were just adding support at the front. So there was no need in going overboard with securing the feet. It’s not like they’re going to somehow “walk” their way out from under the cabinets. Hot glue would have kept them in place for as long as the cabinets were there…again, had I not whacked them with a hammer.

They did require a couple of really hard hits with the hammer to get them loose, but one reason they came loose relatively easily is because they were glued to plastic laminate, which is what IKEA Sektion cabinet boxes are made of. They use plastic laminate for a reason — it’s a very durable, non-porous surface that is easy to keep clean. Since it’s a non-porous surface, that means the hot glue won’t stick as well on it nearly as tightly as it would have had I glued those feet to unfinished plywood or MDF. So I felt confident that I could get them loose with a couple of hard whacks with a hammer.

Once each one was loose, I moved it back 3.5 inches, and re-glued it into place. To do that, I actually just put the new hot glue on the angle where the feet met the floor. In other words, rather than gluing the feet to the cabinet boxes again, I literally glued them to the floor this time. 😀 Hey, if it works, I’ll try it! And this worked just fine.

Once I had all of them set back 3.5 inches and glued into place, I cut the pieces to cover those feet to create the toekick.

Once I had them all cut to length, I removed them, painted them, and then nailed them into place using 1.5-inch 16-gauge nails.

And here are the cabinets with the new, finished toekick…

Where there’s a will, there’s a way, my friends! That’s not just some silly little saying. It’s the truth. Sometimes problem solving can take a few days for me to come up with a solution. But sometimes, the solution is obvious. And sometimes, things may just require a few good whacks with a hammer, and problem solved! 😀

I still have to fill in the gaps at the ends between the cabinets and the side walls. There will be no relief in the weather this weekend, so I hope I can shore up my resolve to get this done. This wall is so close to being finished!

Addicted 2 Decorating is where I share my DIY and decorating journey as I remodel and decorate the 1948 fixer upper that my husband, Matt, and I bought in 2013. Matt has M.S. and is unable to do physical work, so I do the majority of the work on the house by myself. You can learn more about me here.